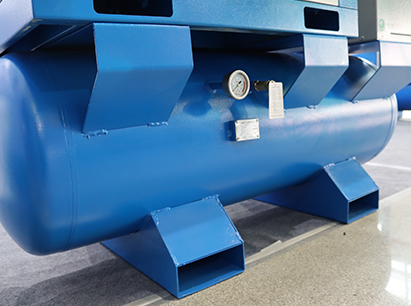

Screw type micro air compressor RM-CM, which connects air compressor, gas tank, refrigerant air drier and precision filter into one set through metal pipes. Users don’t need to connect pipes for second times. It is the most economical choice for laser cutting machine users below 6kw. Easy to install and operate.

| Model | RM-CM-11/16-1 | RM-CM-15/16-1.2 | RM-CM-15/16-1.5 | RM-CM-18/16-1.5 |

| Power (kw) | 11 | 15 | 15 | 18.5/22 |

| FAD (m3/min) | 1.0 | 1.2 | 1.5 | 1.85/2.2 |

| Pressure (bar) | 16 | 16 | 16 | 16 |

| Suitable power | <6kw | <6kw | <6kw | <6kw |

Push the "PLAY" button and see the video

More Details

American famous brand, reasonable dryness, meet the actual production needs, Refrigeration system is more energy saving than the same processing capacity of shell and tube type dryer, plate type high efficiency heat exchanger, make full use of refrigeration.

More Details

Imported filter core, 5-stage filtration, high-efficiency water and oil removal.Filtration accuracy can reach 0.01PPM. High efficiency oil-gas separator, special cylinder design, assembling separation core and oil return device, with service life 6000 hours.

Oil filter which has low pressure design, service life up to 4000hours. High filtration accuracy can effectively protect bearings and screw rotors. The air filter will not change the air flow direction when filtering, and it will directly pass through the filter to reduce pressure loss. It is more energy-efficient than traditional air filters,has a large filtering area , higher precision and long life.

More Details

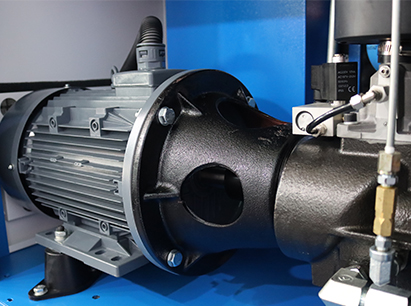

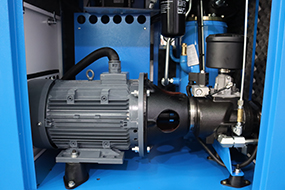

Mainframe adopts large rotors, low speed design,high efficiency, low noise,low vibration,high reliability, small compression ratio, small leakage and high cubage efficiency.

Main motor was carefully selected an IP55 high-efficiency energy saving permanent magnet motor,which is according to the application needs of air compressor. It’s all reached the international first-class energy efficiency standard. Torque and loading can meet special design standards to optimize motor efficiency and power coefficient under load conditions. Comparing to other motors, the optimized coefficient efficiency is about 5%-8%.

More Details

Using frequency converter to adjust the speed, energy saving and power saving can be as high as 42%, which is the most energy-saving air compressor.

Purchase cost ,use cost and maintenance cost to achieve the optimal combination, all priority for users.

View details

Adopt high efficiency Plate-Fins cooling heat area, the heat will be transferred less than 30%. The cooling efficient very good.

View details

Advanced Oil and gas path system

View details

Permanent magnet motor

View details

Easy for Installation, Maintenance